The dew point, also known as the saturation temperature, is the temperature at which water vapor begins to condense. Pressure may be used to represent the amount of any gas in a combination. As nitrogen, oxygen, and water vapor are the principal components of compressed air; total atmospheric pressure comprises the partial pressures of these three gases. While nitrogen and oxygen have fixed quantities, the water vapor concentration is changeable and must be monitored to calculate. Hence, at Perfect, we offer staff that can help with dew point validation.

A compressed air oil content test determines the amount of oil in a compressed air system. Our team conducts tests that determine the amount of oil flowing in a compressed airstream and whether the system meets applicable standards.

When the air or gas cools past the saturation point, i.e., the point where it can store no more water vapor, it begins to condense into liquid water in the compressed air or gas system. Moisture in compressed air utilized in a manufacturing facility creates issues with pneumatic air systems, solenoid valves, and air motors. Hence, to track or identify any water content in the machines, our team conducts water content tests to help avoid any issues and ensure your systems and machines are working in top condition.

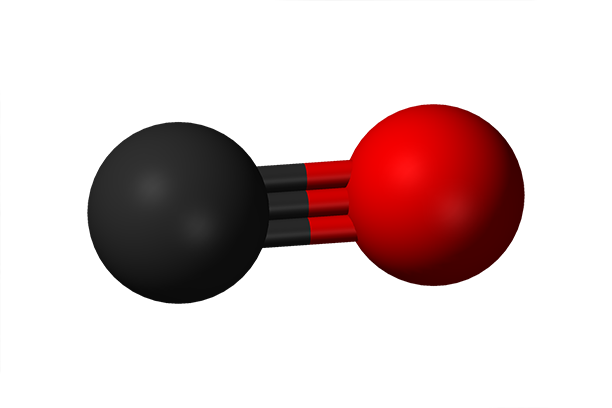

Normal CO2 levels in outdoor air (200-400 ppm) or indoor air (500-2,500 ppm) are not dangerous. However, compressed air with CO2 levels inside the "interior air range" might cause issues in SCBA applications. Moreover, excess CO2 concentration is one of the most prevalent reasons for Breathing air quality issues. Hence, our experts offer carbon dioxide validation tests to ensure complete safety.

The most harmful component in compressed breathing air is carbon monoxide (CO). CO enters the Breathing Air System from the air intake or is created by piston-type compressors overheating. Hence, our experts conduct validation tests to ensure that the CO levels are less than 1 ppm if a good air supply and a well-running, efficient compressor are used.

We provide Nitrogen Gas Validation Services in response to our client's changing and rising demands. Nitrogen gas is utilized to provide an inert gas in vial, ampoule, or WFI tanks and an inert pressure pad in procedures using solvents. Aside from these, Nitrogen Gas is a crucial component widely required in the pharmaceutical sector and many others.

Oxygen is often employed in pharmaceutical manufacturing facilities and is sensitive. The O2 content of compressed air obtained from natural or synthetic air should be within a restricted range. CGA G-7.1 specifies a Grade D acceptable range of 19.5-23.5%.

Sulfur dioxide is the most prevalent breakdown by-product identified during the SF6 gas quality study. Since it is largely unreactive once generated, unlike most other breakdown products, its concentration remains steady over time, making measurement findings more reliable as a condition evaluation metric. As a team of experts, we know that since 2012, all 973-SF6 analyzers have been manufactured to be 'SO2 ready.' This implies that SO2 measurement may be simply added during or post-production, and are team is available to ensure the process is carried out smoothly.

At Perfect, we use Air Velocity Measurement tests to find out the average filter face speed and how uniform it is, the average room airflow speed, and how homogeneous it is. The average airflow speed is found by dividing the sum of all the airflow grid speeds by the number of measurements. We measure the total air velocity for the respected area & calculate ACPH as required.

We conduct filter integrity tests to ensure the quality of the filter & contamination percentage related to the installed area. Our tests and activities are in accordance with the standard set by ISO, EU-GMP.

Perfect is a well-regarded provider of clean room certification services. Our Particle Count Test provides full airborne particle count cleanliness classification. The test's purpose is to determine the actual particle count within the facility at the time of the test. According to ISO 14644 and EU GMP, the test determines particle count based on As-Built, At-Rest, and Operational conditions.

We undertake recovery testing for clients across sectors. These experiments illustrate the ability of a clean room to eliminate particles by purging the space with filtered air. It also indicates if the space can be transformed from "dirty" to "clean" within the allotted time. Our professionals have extensive knowledge and provide consumers with superior service. Our company's ultimate objective is to provide total client satisfaction through efficient service delivery and the provision of the finest selection of clean room equipment. We ensure that the clean room facility of the customer is operating properly and precisely.

We conduct an Airflow pattern Test to determine the direction of airflow. The objective of the airflow visualization test is to demonstrate the real airflow pattern within the unidirectional clean room. The test can also illustrate the influence of equipment on airflow. The test identifies the airflow patterns within a room using ISO 14644 recommendations.